|  |

|

Menü |

| Clamping Systems |

| Acrobat Assembly Robot |

|

|

| ||||||

| Bag Lifting With Vacuum Tube Lifter | Vacuum Lifting Device For Craft Bag | Rubber Bale Lifting With Vacuum Hose Lifters | Natsu Vacuum Tube Lifters | |||||

| NATSU VACUUM LIFTING SYSTEMS | ||||||||

|  |

|

||||||

| Coils Lifting & Turning | Reel Lifter For Overhead Crane | Coils,Reel Manuplator | Reel Lifting Systems | |||||

| NATSU VAKUMLA KALDIRMA VE TAŞIMA SİSTEMLERİ | ||||||||

|  |

|

Vacuum Lifting Systems for Sheet Metal | Sheet Metal Lifter For Overhead Crane | Vacuum Lifting Machine For Sheet Metal | Laser Cutting Workbench Loading System With Vacuum Lifter | ||

| NATSU VACUUM LIFTING SYSTEMS | ||||||||

|

|  |

||||||

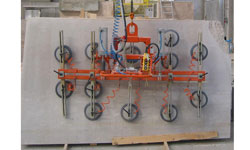

| Vacuum Lifting Machine For Marble Strip | Block Cutter Machine Unloading With Vacuum | Marble Vacuum Lifter | Marble Strip Vacuum Lifting | |||||

| NATSU VAKUMLA KALDIRMA VE TAŞIMA SİSTEMLERİ | ||||||||

NATSU MACHINE - VACUUM LIFTING SYSTEMS Founded in 1998, NATSU Machine; Vacuum lifting and transport machinery in our country is one of the first local companies in the production of.Vacuum lifting and transport systems at different levels of production in the industry is used.Natsu standard product range large enough to cover all fields of applications of the machine. Natsu machine ; in our country, innovations in the field of transport carriers Vacuum lifting and vacuum contributed quite a lot of companies that use usually have high standards. These Lifters are mostly efficiency, automation and emphasis on employee working conditions used by businesses. These companies use products that must meet extremely stringent quality and safety requirements. Natsu machine working in this field to meet these standards from the beginning, constantly renew itself and continues to improve.

| ||||||||

| NATSU VACUUM LIFTING SYSTEMS | ||||||||

|

|

| ||||||

| Natsu Vacuum Lifters For Rubber | Jib Crane & Vacuum Hose Lifters | Vacuum Lifting Device For Sack | Flour Sack Lifting With Vacuum Tube Lifter | |||||

| NATSU VACUUM LIFTING SYSTEMS | ||||||||

|

|

| ||||||

| Vacuum Tube Lifter For Reel Lifting | Aluminium Jib Crane & Coil Lifter | Reel Handling Equipment | Drum Handling-Coil Lifting | |||||

| NATSU VAKUMLA KALDIRMA VE TAŞIMA SİSTEMLERİ | ||||||||

|

|  |

||||||

| Jib Crane & Vacuum Lifter for Laser Cutting Machine | Vacuum Jib Crane | Laser Cutting Workbench Loading With Vacuum | Sheet Metal Carrying | |||||

| NATSU VACUUM LIFTING SYSTEMS | ||||||||

|

|

|||||||

| HOVMAND TURKEY | HOVMAND TURKEY | |||||||

| NATSU VAKUMLA KALDIRMA VE TAŞIMA SİSTEMLERİ | ||||||||

Vacuum transport and lifting machines; all in the manufacturing industry at every stage of the production process is needed.NATSU Machine, with an expert staff, customers, fast,accurate, and competent by providing information on alternative project solutions recommends a high quality and reliable products. Natsu Machine ;Marble lifting and carrying vacuum, vacuum, sheet metal removal and transportation, glass lifting and carrying the vacuum ,remove the vacuum box,the vacuum holder systems wood-mdf partner and offers products that appeal to a sector with move vacuum.Outside of the vacuum system , jib cranes, lifting cranes and electric chain sales and service of vacuum pumps and vacuum handling systems providing natsu, special projects, Chemistry,automotive,sectors such as vacuum lifting and handling systems for the tire industry provides support for special productions.Manipulators box,bag lifting systems,jib crane, vacuum systems,vacuum hose to remove chemical bag lifters,vacuum suction,light crane systems and overhead crane and increase its product range with fixed.,robot vacuum automatic loading systems, such as a Cartesian system in the transport of any material customers experienced and reliable solution partner.

| ||||||||

| NATSU VACUUM LIFTING SYSTEMS | ||||||||

|

|  |

||||||

| Vacuum Lifting Machine For Marble Slab | Marble Slab Loading Systems With Vacuum Lifter | Marble Vacuum Lifter With Jib Crane | Vacuum Jib Crane | |||||

| NATSU VAKUMLA KALDIRMA VE TAŞIMA SİSTEMLERİ | ||||||||

|

|  |

||||||

| Vacuum Lifter For Glass | Jib Crane & Glass Vacuum Lifter | Glass Lifting Equipment | Glass Handling | |||||

| NATSU VACUUM LIFTING SYSTEMS | ||||||||

|

|  |

||||||

| Vacuum Lifter for Wood Planks | Jib Crane And Vacuum Lifter For Wood Planks | vakumat-wood-lifting | Vacuum Lift for Wooden Door | |||||

| NATSU VAKUMLA KALDIRMA VE TAŞIMA SİSTEMLERİ | ||||||||

During the production phase , the materials, remove, move, and the place always creates a problem. Vacuum lifters, which is designed to cope with this problem; to transport materials from one place to another efficient, cost-effective and often offers a more secure method. This can not only save you time and increase profits, but also more effective in reducing employee fatigue and injuries, productive and allows the creation of a safe working environment.Vacuum handling systems, Marble, sheet metal, glass, wood, automotive, white goods, from the different levels of production in many sectors such as chemistry in the form of manual or automatic systems are used. | ||||||||

| NATSU VACUUM LIFTING SYSTEMS | ||||||||

|

|  |

||||||

| Natural Stone Lifter With Vacuum Ejector | Vacuum Lifter For Marble | Natsu Vacuum Lifting Systems For Marble | Natsu Vacuum Lifting Machines | |||||

| NATSU VAKUMLA KALDIRMA VE TAŞIMA SİSTEMLERİ | ||||||||

|

|  |

||||||

| Mobile Jib Crane | Mobile Vacuum Systems | Mobile Vacuum Lifter | Mobile Vacuum | |||||

| NATSU VACUUM LIFTING SYSTEMS | ||||||||

|

|  |

||||||

| Natsu Jib Crane | Wall Muontaed Jib Crane | Light Bridge Crane | Light Bridge Crane & Vacuum | |||||

| NATSU VAKUMLA KALDIRMA VE TAŞIMA SİSTEMLERİ | ||||||||

| Vacuum lifting and transport systems in our country, the efficiency, automation and emphasis on employee working conditions is being used by businesses. Natsu Machine, with the leadership of the system in question in Turkey continues. In developed countries especially in the transportation of many products in our country very commonly used vacuum lifting and transport systems efficiency, automation and emphasis by businesses on employee working conditions was introduced. Natsu Machine, which is a leading organization in the production of such systems; vacuum lifting and transport systems production. In addition, jib cranes-light type (l tons), lightweight overhead cranes (l tons) of German origin with a production capacity of electric chain winches (liftket) and again Vahle German brand power transmission systems, cable drum making the sale. Vacuum handling systems, Marble, sheet metal, glass, wood, automotive, white goods, are used in various industries such as chemical. In different levels of production, manual or auto - MATIC systems may be preferred. There are many advantages of moving in a vacuum. These employees will therefore not be a burden to the energy of the elements during the day to make an optimum use, not requiring to bind as a result of the acceleration of the migration process, the product shall not be binding to any damages resulting from labor saving, (the only person the job of up to 4 people can be on some systems) can be considered as. Standard manual and automatic machinery and equipment as well as special solutions are also offered. | ||||||||

| NATSU VACUUM LIFTING SYSTEMS | ||||||||

|

NATSU MAKİNA İNŞ.A.Ş.

| |

Uluönder Mahallesi 3072 Sokak No : 3/1 ESKİŞEHİR |

|

Tel: 0 222 340 02 18 Fax : 0 222 340 21 18 |

|

www.natsu.com.tr info@natsu.com.tr |

|